Steering and Control Systems

Fluxgate Compass

Fluxgate compass

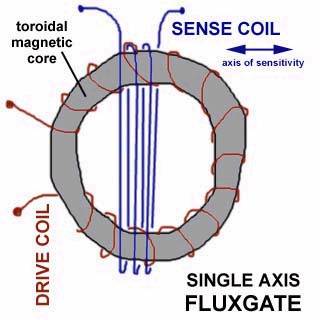

The fluxgate is one kind of magnetic field sensor

which combines good sensitivity with relative ease of construction. The basic

principle is to compare the drive-coil current needed to saturate the core in

one direction as opposed to the opposite direction. The difference is due to

the external field. Full saturation is not necessary; any nonlinearity will do.

As the core approaches saturation, the signal picked up in the sense coil will

show the nonlinearity. For instance, if you put a sine-wave into the drive

coil, the sense coil would detect harmonics of the fundamental frequency;

increasing in strength relative to the fundamental as the core becomes more

fully saturated.

Fluxgate compass

Different from the course detector that picks up the

magnetic field from the compass card magnet, the fluxgate compass picks up the

Earth’s magnetic field directly.

The sensor coil is either mechanically gimballed or has a floating ring core .

This will prevent an uneven distribution of the magnetic field in the sensor

coil when the boat is rolling and pitching. Compared to a magnetic compass,

however, the fluxgate compass is more sensitive to the motions of a vessel. In

rough sea conditions or in sharp turns at high speeds, the sensor may be

temporarily displaced from the horizontal plane.

A distorted and unstable heading input to the

autopilot is the resulting effect. A lot of attention has been paid to reduce

this effect when designing the Fluxgate compass and it has proven to be

successful. The optimum performance is accomplished with a rate sensor

stabilized fluxgate compass.

Except from the Rate Compass, fluxgate compasses are

not recommended as autopilot compass on steel boats, mainly due to lack of

efficient “heeling error” compensation. This compensation is needed when a

magnetic heading sensor is mounted on top of the wheelhouse or in the mast.

The Rate Compass is in principle a combination of a

solid state rate sensor and a fluxgate sensor, where the rate sensor is slaved

to the fluxgate sensor.

The rate sensor will momentarily pick up any angular

changes in azimuth, but is almost unaffected by roll and pitch.

As the “rate heading” will drift, the fluxgate sensor

is needed to maintain the (magnetic) heading. However, as the rate sensor is

the primary “heading” source, the fluxgate signal can be more dampened and thus

it will not contribute to the instability caused by heavy rolling and pitching.

The Rate compass gives a more stable and precise autopilot

steering on any type of boat. It also eliminate the

effect of the distorted horizontal magnetic field at high latitudes and the

well known swing phenomena when on autopilot steering.

It can also be used as “stand alone” compass to

provide a stable heading input to a compass repeater, a radar

or other equipment.

However, care should be taken when using it on bigger

steel boats that can have strong local disturbing magnetic field that makes a

good calibration of the fluxgate impossible.

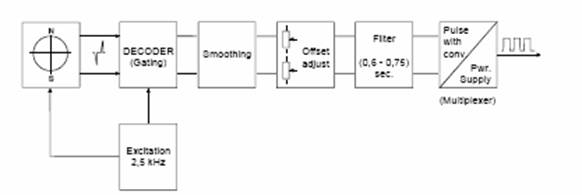

Explanation

to Block diagram

Refer to above figure.

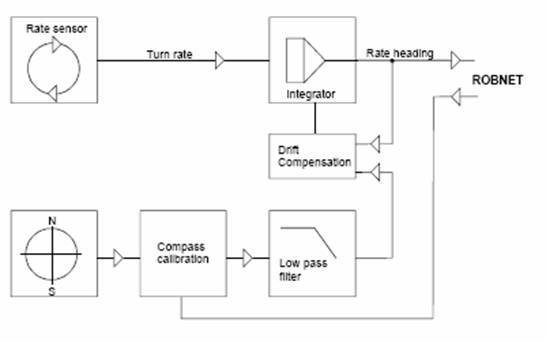

The rate sensor generates a rate of turn signal that

is converted to a heading angle by the integrator circuit. This output is

called Rate heading.

The heading output from the fluxgate sensor, is called

Flux heading. It is filtered by a low pass filter with a time constant.

The Flux heading is calibrated and calibration data

are stored in the EEPROM in the compass.

The high dampening of the Flux heading will suppress

unstable heading signals caused by the vessel's roll and pitch.

The reduced response from the Flux heading is

compensated for by the Rate sensor. The Rate sensor is very sensitive to any

movement (turn) in the horizontal plane, but almost insensitive to roll and

pitch.

As the Rate heading is a relative angle it has to be

coupled to the Flux heading.

This coupling is made in the Drift Compensation

circuit which serves two purposes;

1. It will prevent the Rate heading from drifting away

due to internal (temperature) drift in the Rate sensor.

2. When a big course change is made and there is a

difference between the integrated Rate heading and the measured Flux heading,

the difference will be coupled into the Rate integrator as a bias offset for

the Rate heading to make it equal to the Flux heading.